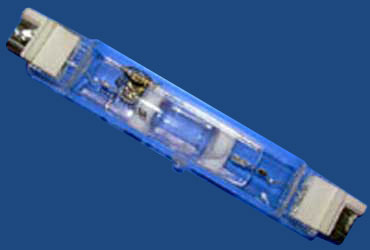

Metal halide UV lamps are used in automobile lighting, where are high-intensity discharge (HID) lamps are commonly known as "xenon headlamps" due to the use of xenon gas in the bulb instead of argon.

Another widespread use for such lamps is in photographic lighting and stage lighting fixtures, where they are commonly known as MSD lamps and are generally used in 150, 250, 400, 575 and 1,200 watt ratings, especially intelligent lighting.

3LCD and DLP video projectors use metal-halide lamps as their light source.

The color temperature of a metal-halide lamp can also be affected by the electrical characteristics of the electrical system powering the bulb and manufacturing variances in the bulb itself. If a metal-halide bulb is underpowered, because of the lower operating temperature, its light output will be bluish because of the evaporation of mercury alone. This phenomenon can be seen during warmup, when the arc tube has not yet reached full operating temperature and the halides have not fully vaporized. The inverse is true for an overpowered bulb, but this condition can be hazardous, leading possibly to arc-tube explosion because of overheating and overpressure.

Ballasts

Many fixtures use an inductive ballast similar to those used with fluorescent lamps. This consists of an iron-core inductor. The inductor presents an impedance to AC current. If the current through the lamp increases, the inductor reduces the voltage to keep the current limited.

Electronic ballasts are lighter and more compact. They consist of an electronic oscillator which generates a high frequency current to drive the lamp. Because they have lower resistive losses than an inductive ballast, they are more energy efficient. However, high-frequency operation does not increase lamp efficacy as for fluorescent lamps.

Pulse-start Metal halide LED Lamps don't contain a starting electrode which strikes the arc, and require an ignitor to generate a high-voltage (1–5 kV on cold strike, over 30 kV on hot restrike) pulse to start the arc. Electronic ballasts include the igniter circuit in one package. American National Standards Institute (ANSI) lamp-ballast system standards establish parameters for all metal-halide components (with the exception of some newer products).